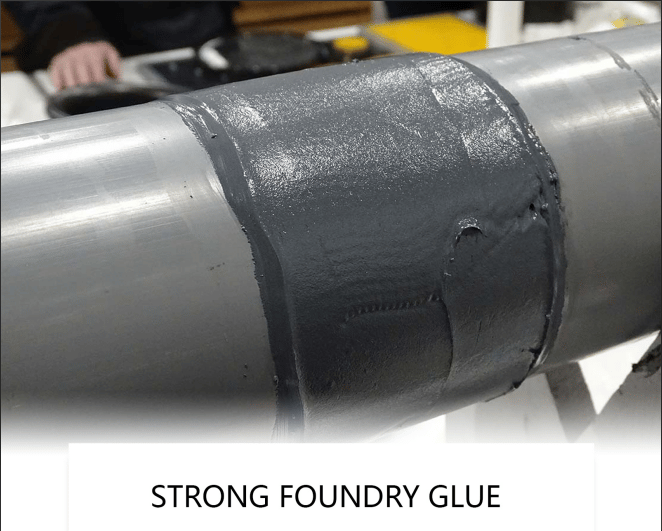

Our metal casting glue contains glue A: epoxy resin, polymer resin; glue B: curing agent, additives. It can provide excellent adhesion, ensuring that metal parts are firmly bonded and durable. Its use is very simple: First, open the casting glue, squeeze out glue A and glue B with a push rod, and stir the colloid thoroughly. Use a scraper to evenly apply castor glue to the cracks of the metal. Finally, use sandpaper to polish the surface of the repair area. And it can withstand extreme high temperatures and is suitable for various high-temperature casting environments.

Product Description

【Hight-Strength Bonding】Formulated for extreme durability, bonding metal, wood, ceramic, and most tough materials with unbreakable hold—even under stress or vibration, providing Long-Lasting Repair Effects.

【High Temperature Resistance】Withstands high temperatures, this repair glue offers remarkable durability. Once fully cured, it exhibits an iron like hardness and provides a consistent bond line thickness. Not exceeding 150°C

【Fast-Setting & Gap-Filling】Thick, non-drip formula sets in minutes and fills uneven surfaces or small cracks for seamless repairs.

【Easy to use】1. Open the caster glue first, use the push rod to squeeze out the A glue and B glue, and stir the colloid thoroughly.

2. Use a scraper to evenly apply castor glue into the cracks of the metal.

3. Finally, use sandpaper to polish the surface of the repaired area.

【Application】Our glue is specifically formulated for iron and steel casting, effectively addressing issues like sand holes and pores. Additionally, it can be used for repairing fuel tanks, plumbing systems, concrete breaks, and more.